The John Lewis Partnership has announced a three-year trial with the start-up agri-tech business Small Robot Company, which will see the use of ‘autonomous farmbots’ Waitrose & Partners’ Leckford Estate in Hampshire.

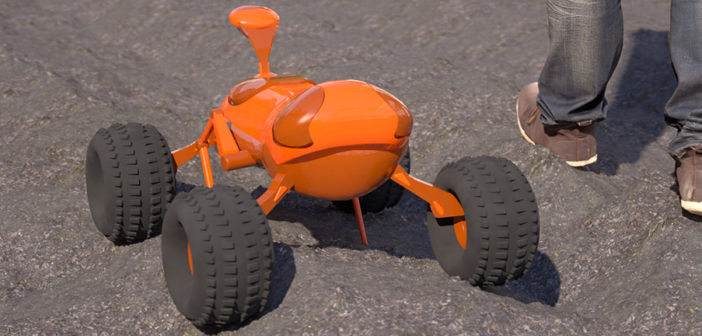

During the trial, the Small Robot Company’s three small robots; Tom, Dick and Harry, will l test their state-of-the-art learning and farming technology on a one-hectare field of wheat. Initially a prototype Tom robot, which is fitted with cameras and weighs just ten kilograms, will gather topographical data, eventually creating a plant-by-plant view of the field. The Small Robot Company can then further develop its machine learning systems, while building also new prototype robots.

The data gathered by the Tom robot will be used to develop an AI system called Wilma, which will eventually guide the three robots, allowing them to farm autonomously. As well as increasing precision, efficiency and productivity, the small robots are expected to deliver considerable environmental benefits, such as reduction in compaction and soil damage.

Andrew Hoad, Partner & Head of the Leckford Estate, commented, “The Waitrose & Partners farm has a long history in producing a wide variety of high quality crops. We work hard to farm in harmony with the environment and our vision for sustainable farming is aligned to what the Small Robot Company is trying to achieve.”

Sam Watson Jones, co-founder of Small Robot Company and a fourth generation Shropshire farmer, added, “Together, we will be working to re-imagine food production. We’re on the cusp of a fourth agricultural revolution, taking farming into the digital age, with British ideas and British technology at the helm.”

Photo caption: Artist’s impression of the Tom robot in action

Photo Credit: Small Robot Company

The post Waitrose to trial small farm robots appeared first on Hort News